Based on the latest innovative Industry 4.0 technology all process data in the different process steps of a rolling mill can be integrated in one system. Know how generation based on the correlation of several variables can be automatically provided including the specific weight factors and applied in a continuous improvement cycle.

The system provides a new QES™ data base using powerful algorithms to get more out of the existing data. The data base can store mill data for up to 10 years. Before storing data it is always verified and validated by a dynamic rule based verification set. Hereafter the resolution is adapted to the needs of the quality & production team. As next step data is linked together with context and especially the genealogy. Finally the data packages are compressed without any loss and stored for all process steps of the mill.

This specific preparation and storage of data allows the user to get answers to queries in seconds over all different process steps from steelmaking, casting, hot mill, pickle and coating to finishing. According to the experience of our users, it is often more than one variable which contributed to deviations in quality. Also it turned out that frequently the contributing variables are located in different process steps. E.g. some are from casting and at the same time from hot mill reheating furnace and maybe one temperature in the coating line. Each variable contributes with different weight factor to the deviation in quality. This is an indication for severity and also a clear direction for corrective actions.

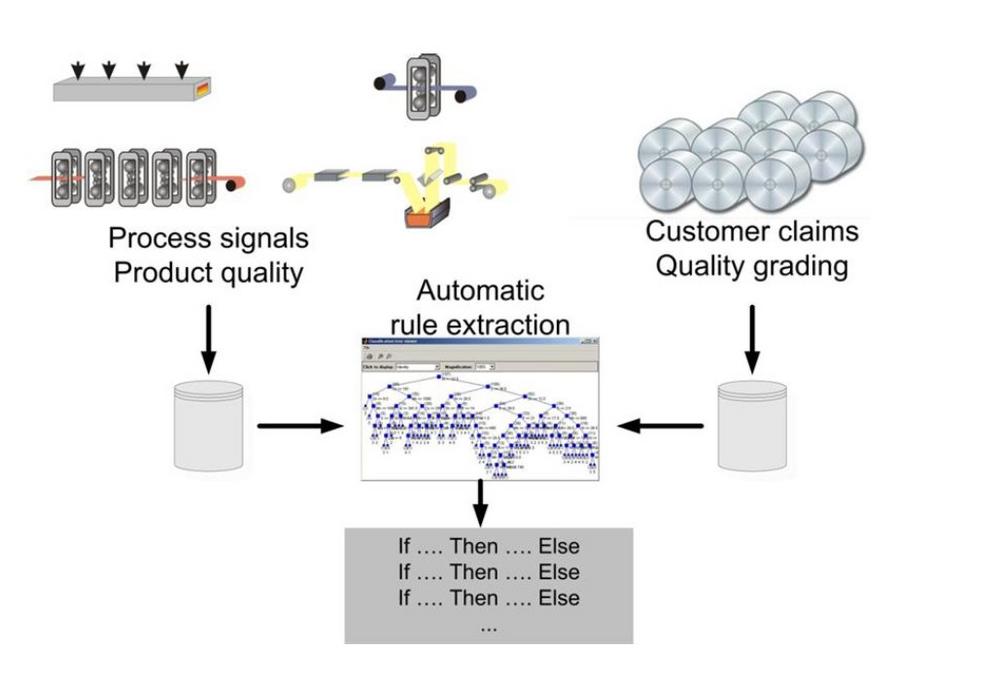

QES™ DataCorrelator module provides automatically all this necessary information as a transparent decision tree. The decision tree is automatically calculated using neuronal networks and indicates all weighing factors for different levels of the tree, which can be used for setting of rules thresholds. The module even provides automatically a proposal for a new rule set which can be used in the quality decision in each process step. In the following example customer claims are used to generate new rules or a complete new “if/than” rule set.

(Image 1: Automatic generation of rules by “Machine Learning Algorithm’s“ for the rolling mill)

Once the knowhow is generated, it cannot get lost after a period of time, but will be permanently stored in the rule set of the mill. Knowledge can be retrieved from the system easily for future “on the spot” analyses or for continuous adaptation to changed conditions.

Additional QES™ software modules like for automatic product (heat/slab/coil/sheet) release or grading and for the re-assignment of downgraded products, for statistical process control including the intelligent expertise management allow establishing a comprehensive quality management solution.

For the first time this system configuration offers continuous adaptation to always faster changing requirements of markets and especially high end customers. And this is not only related to frequently changing product specifications, but also to smaller orders down to 1 product lot, which needs a very flexible and short-term adaptation of process and quality control. Not foreseeable process disturbances are today much more critical but can be handled if the process conditions are transparent and accessible for all users online.

Fast and positive acceptance by all quality system users in the mill, can only be achieved if the system fulfills all ergonomically and todays’ usability requirements. Easy to use allows each quality and production engineer to maintain and operate the system completely autonomously. This includes the generation of new and the maintenance of existing specifications, norms and customer specific requirements. Besides the quality targets all modifications have to include the economical view, which means to analyze and report exactly the produced output, the internal downgrades and the verified claims.

(Image 2: Continuous quality improvement in rolling mills)

Already before new quality specifications are applied in the mill a sophisticated off line simulation can predict exactly how the new settings will perform. It calculates not only the “according to specification” production but also ensure that reasons for customer claims will not be repeated. Modifications can be implemented and tested in minutes. Therefore users can follow the changes of the market or specific customer requirements flexibly and extremely fast.

About QuinLogic

Company is focusing exclusively on quality software modules in rolling mills. Meanwhile many of the world class steel and aluminum mills are QuinLogic customers. Since 2016 the company is member of the SMS group.

QuinLogic GmbH

Tel.: +49 2405 47999421

E-Mail: info@QuinLogic.de

www.QuinLogic.de

QuinLogic is an independent company developing quality management software and providing services for all aspects of surface inspection.

The company was established in 2008 in Aachen/Germany by a team of engineers who have influenced the development of automatic surface inspection in the steel, aluminium and paper industries for more than a decade.

QuinLogic offers manufacturer-independent service during operating trials, evaluations of inspection systems, integration of systems as well as optimization of detection and classification systems.

In addition, the company has developed a rule-based decision-making software, which – using data from most different sources – guarantees optimal use of production material.

QuinLogic GmbH

Heider-Hof-Weg 23

52080 Aachen

Telefon: +49 (2405) 4799940

Telefax: +49 (2405) 47999444

http://www.quinlogic.de

Telefon: +49 (2405) 479994-0

Fax: +49 (2405) 479994-44