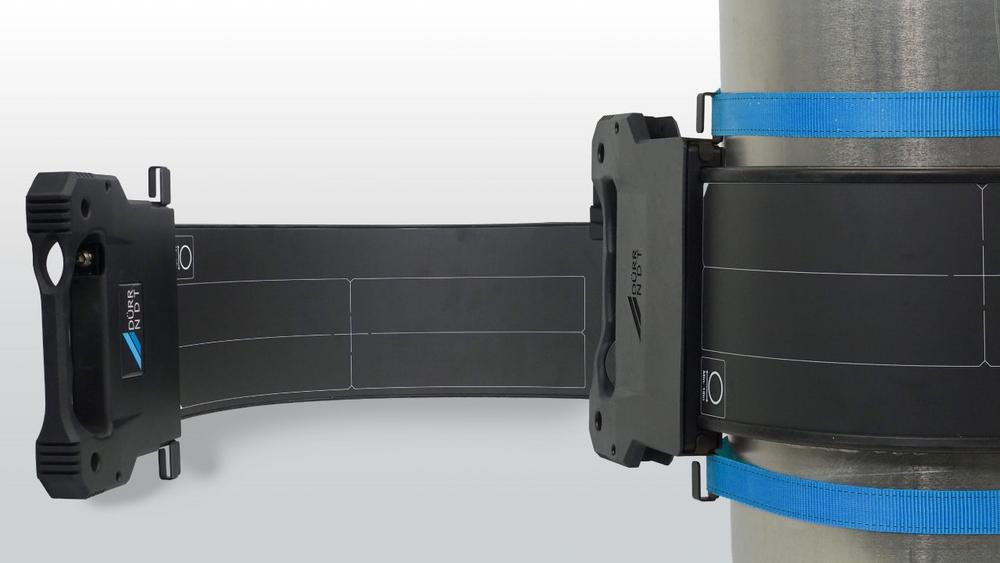

Both detectors can be bent continuously from flat to a 150 mm respectively 300 mm diameter in one direction, with exposures possible on both sides. A simple mounting system allows the detectors to be easily attached to a pipe with 2 straps and then rotated along the weld seam.

With a pixel pitch of 99 µm, a basic spatial resolution (SRb) of 100 µm is achieved, making them perfectly suited for weld inspection in accordance with DIN EN ISO 17636-2 (Class B). Due to the bendability, typical applications are pipeline, tank and vessel inspections, but also weld seam inspections on straight objects are possible, as the detector can also be used in a flat position.

Thanks to the integrated shielding, the detectors are suitable for X-ray sources up to 450 kV, with a maximum frame time of 180 seconds. As they are dust-tight and waterproof (IP67), battery-powered and have wireless data transmission, they are well prepared for tough applications in the field.

Bendable detectors can replace conventional X-ray films in a wide range of industries, from oil and gas to power generation, chemicals and aviation, and optimize inspections through fast image acquisition and software-assisted analysis.

Like all digital X-ray systems from DÜRR NDT, the bendable detectors are also operated with our proven D-Tect X inspection software. Special and easy-to-use functions such as multi-gain calibration always ensure the highest possible image quality. Powerful and intelligent tools, such as the X-filter for fast image optimization, make image evaluation simple and efficient.

DÜRR NDT is a German manufacturer of systems for industrial radiography in the field of non-destructive testing (NDT) and provides Computed Radiography (CR) scanners, Digital Radiography (DR) flat panel detectors (DDAs) and X-ray inspection and analysis software. DÜRR NDT also offers X-ray film processors for mobile use and the unique REACH compliant environmentally-friendly film processing chemistry. New is the cloud-based management software DRIVE NDT for all NDT inspection methods to organize and control the complete NDT workflow including individual test reports, staff, customer and device management, and much more.

DÜRR NDT GmbH & Co. KG

Höpfigheimer Strasse 22

74321 Bietigheim-Bissingen

Telefon: +49 (7142) 99381-0

Telefax: +49 (7142) 99381-299

http://www.duerr-ndt.de

Marketing

Telefon: +49 (7142) 99381170

E-Mail: roth.a@duerr-ndt.de

![]()