In order to meet medical requirements, we offer individual silicone-molded system solutions consisting of connectors, overmolding as well as cables as qualified cable assemblies while optionally providing laser markings in accordance with Unique Device Identification (UDI).

ODU silicone overmoldings for the medical industry

The company has evolved over the years to become a specialist in custom overmolding. The tools developed and manufactured at ODU for straight or angled designs are designed (depending on the application) for samples, small series or large series production.

Since applications in the medical sector have to meet special hygienic and mechanical requirements, the contact specialist’s silicone overmolding connects the ODU connector to the certified silicone cable and combines the best feel with hygiene and resistance. The silicone overmoldings are easy to clean, flexible, insensitive to extreme temperatures and cannot be peeled off or detached even after the required autoclaving cycles (steam sterilization at up to 134 °C and 3,040 mbar). The biocompatibility with regard to cytotoxicity testing (outgassing) according to DIN EN ISO 10993-5 is confirmed by an external testing laboratory.

The complex process of silicone overmolding enables an absolute tight yet flexible connection of the silicone cables to the connector (kink protection according to DIN EN ISO 61010-031 as well as increased strain relief) and is adapted to the specific material properties of the silicone cable.

Any quantity and length

The ODU silicone portfolio includes numerous silicone cables from qualified suppliers and includes the required certifications as well as further inspections regarding surface condition, adhesion and cleaning so that no further certification procedures are required on the customer side. Through appropriate partnerships, ODU can always offer the cable assemblies in consistent quality (for example, adhesion to cable jacket) and already in small quantities. The cable assembly is available in any length.

Advantages of the ODU silicone overmolded system solution

Customers benefit from the following advantages with the ODU silicone overmolded system solution:

- Certified quality of the silicone-molded complete solution (biocompatibility with regard to the cytotoxicity test (outgassing) according to DIN EN ISO 10993-5 as well as kink protection according to DIN EN ISO 61010-031)

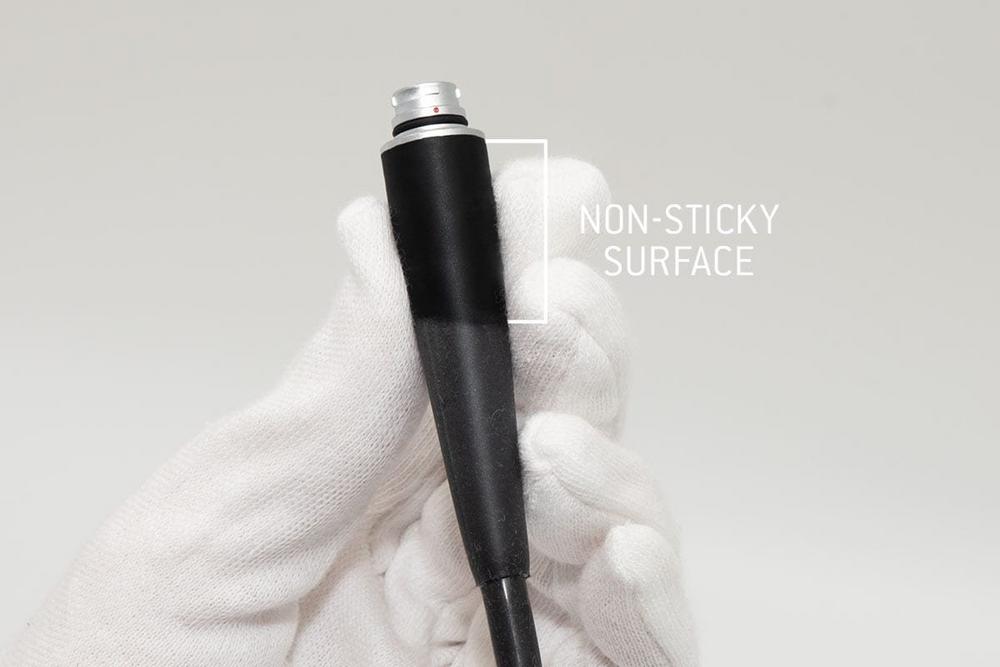

- Pleasant, tack-free feel of the silicone overmold (even for patterns or small batches) without stick-Slip-Effect

- Fast availability

- Fair pricing (incl. cost reduction vs. individual acquisition)

- Length neutrality

- Reduced effort as no certification is required, the supply chain is limited to one contact and only one part number needs to be managed by the customer

For more information, visit https://odu-connectors.com/technologies/silicone-overmolded-system-solutions/ or visit us at Compamed taking place Nov. 13-16, 2023, at Booth P19 in Hall 8A.

The ODU Group is one of the world’s leading suppliers of connector systems, employing 2,600 people around the world. In addition to its company headquarters in Muehldorf a. Inn (Germany), ODU also has an international distribution network, production and product development sites in Sibiu/Romania, Shanghai/China, Tijuana/Mexico and Camarillo/USA. ODU combines all relevant areas of expertise and key technologies including design and development, machine tooling and special machine construction, injection, stamping, turning, surface technology, assembly and cable assembly. The ODU Group sells its products globally through its sales offices in Austria, China, Denmark, France, Germany, Hong Kong, Italy, Japan, Korea, Romania, Sweden, UK and the US, as well as through numerous international sales partners. ODU connectors ensure a reliable transmission of power, signals, data and media for a variety of demanding applications including medical technology, military and security, automotive, industrial electronics, and test and measurement

ODU GmbH & Co. KG

Pregelstraße 11

84453 Mühldorf a. Inn

Telefon: +49 (8631) 6156-0

http://odu-connectors.com/de/

Product Marketing Specialist

E-Mail: lisa.huber@odu.de

![]()