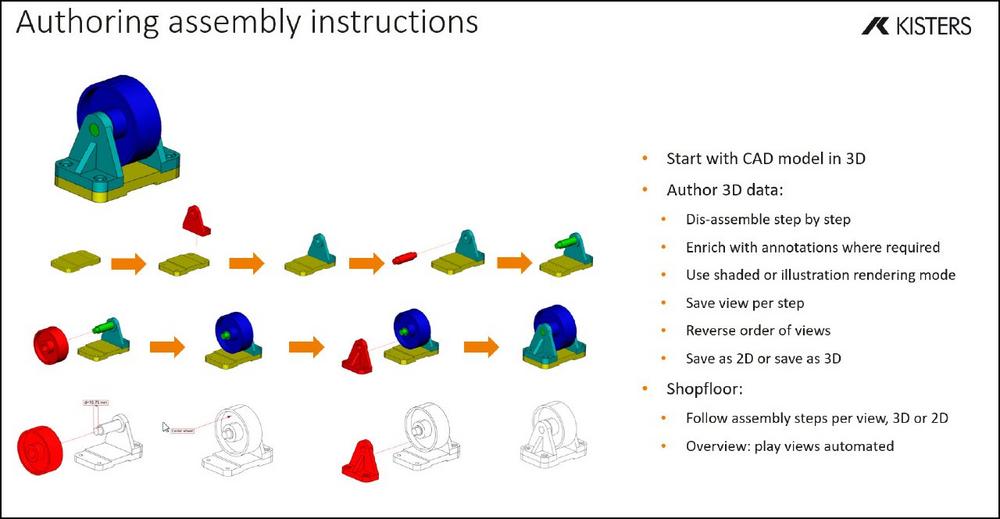

To prepare the data utilizing 3DViewStation one will first pull apart the individual segments of the assembly step by step and save them as individual views. Camera positions can be selected, parts can be faded in and out and repositioned. Also, 3DViewStation enables you to do markups, dimensions or free texts that can be applied to the individual steps necessary for the assembly construct. The result is a disassembly instruction that becomes an assembly instruction by inverting the order of the views. The workers in the production department first get an overview of the assembly sequence by animated playback of the views using the play function. Afterwards, the assembly is carried out step by step according to the individual views.

According to Craig Impastato, U.S. Sales Director for KISTERS, “It is important that the effort required to handle changes to the underlying assembly is kept to a minimum. 3DViewStation allows you to save the views separately from the geometry. If the CAD model changes, one can simply re-import the previously saved views. If there were only geometric changes, one is now already done and the assembly instructions are updated. If a part was removed, it automatically disappears from all views. If there is a new part, it only has to be added in the affected views. The basic structure is therefore always preserved and can be adapted with minimal effort. Often, the authors of these assembly sequences work with the 3DViewStation Desktop version and the production staff with the 3DViewStation WebViewer version, which does not require any installation on the end device and always uses the latest data”.

In summary, users of KISTERS 3DViewStation get more out of the 3D models of the design. With minimal preparation, the manufacturing department can access the enriched CAD data. 3D assembly instructions make complex production processes easy to understand and greatly simplify employees’ day-to-day work assignments. The end result is increased production, efficiency, less defect, higher quality and thus competitive advantages.

Known for its modern user-interface, high performance viewing, advanced analysis and integration capabilities into leading systems, 3DViewStation ships with current and mature importers for a broad range of 3D and 2D formats including Catia, NX, Creo, SolidWorks, SolidEdge, Inventor, Revit, JT, 3D-PDF, STEP, DWG, DXF, DWF, MS Office and many more.

The latest developments of 3DViewStation can be reviewed in more detail at:

https://www.3dviewstation.com/news/blog.html

According to Impastato, KISTERS 3DViewStation is continuously enhanced in response to customer needs and requirements. It is available as Desktop, VR-Edition and HTML5 WebViewer product versions plus the online collaboration tool VisShare. All product flavors are intended to be used together with a PLM, ERP or other management system product configuration or service and spare part applications, providing all necessary APIs. For cloud, portal and web solutions, there is an HTML5-based WebViewer solution available, which does not require client installation. All file formats can be used in combination with the intelligent navigation and hyperlinking features to address the needs of complex integration scenarios.

With more than 25 years of success in the market as a provider of superior visualization solutions from desktop to mobile, KISTERS has become one of the top players in the visualization industry. The company’s clients range from small firms to well-known multinationals, comprising more than 3,000 customers and over 200,000 installations worldwide. The 3DViewStation’s easy-to-use interface is suitable for all user groups and 100% customizable to everyone’s specific requirements. In addition, KISTERS offers expert advice and support in concept development based on client requirements.

KISTERS AG

Pascalstraße 8 + 10

52076 Aachen

Telefon: +49 (2408) 9385-0

Telefax: +49 (2408) 9385-555

http://www.kisters.de

E-Mail: Germar.Nikol@kisters.de

![]()