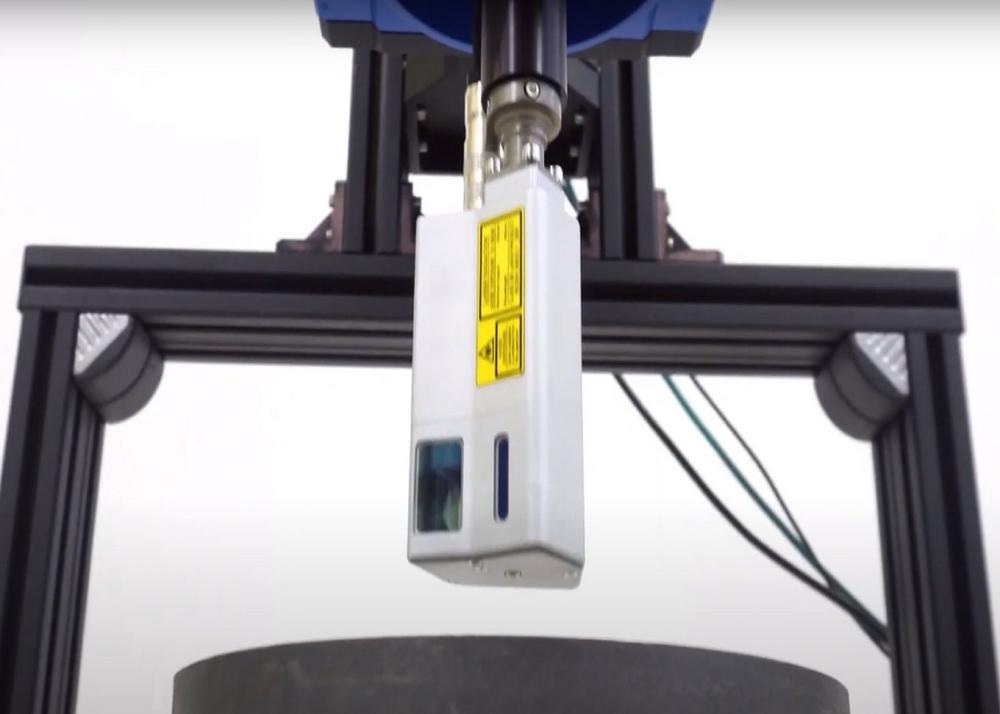

The mechanical hardware, including the mounting frame and main housing with interfacing connectors for 24V DC power and fieldbus, forms part of the Riftek supplied system. As well as the probe software, an RS422-to-PROFINET IO module interfaces the 2D laser sensor to the PLC. For this set-up, the customer preferred to use a Siemens S7-1200 PLC although other manufacturer’s PLCs of choice could be used. GSD files and a comprehensive installation manual are also part of the supply. The probe software and the IO module combine to provide a data packet allowing the graphical display of the component being measured and a file output for use in further analysis software. The system supplied is fully adaptable for vertical or horizontal orientation to suit the customer’s project demands.

The final system is part of Riftek’s RF096 series custom build range that also includes other versions of the RF627 and other laser sensors that are specifically adapted as sub-systems for multiple measurement of customer’s component parts, typically as part of high-throughput manufacturing processes. Other examples of the RF096 sensor measurement series include fully machine integrated systems for welding lines and automated assembly measuring length, diameter, proximity etc., as well as component profile and thickness measurement, debris monitoring and more. Other systems can include manual operation with footswitches, hand controls or keypad/mouse activation to provide measured results recorded and displayed on a GUI as actual dimensions or as pre-set go or no-go values.

Ixthus Instrumentation Ltd provides a comprehensive sales and technical support service across Riftek’s comprehensive range of optoelectronic 2D and 3D laser measurement devices and systems from single components to complete systems such as the RF609 series. Ixthus also represents many other leading suppliers of non-contact sensing technologies for force, torque and vibration providing measurement application solutions across industry, research, military, aerospace, marine, oil and gas, mining, hoist and crane, automotive and more. For more information email info@ixthus.co.uk or visit www.ixthus.co.uk.

Ixthus works closely with leading global suppliers of non-contact sensing technologies as well as force, torque and vibration sensor and transducer manufacturers, providing a complete service with its knowledgeable technical staff available to solve customers’ measurement problems – from the first enquiry to complete after-sales support.

Ixthus Instrumentation Limited

The Stables, Williams’ Barn, Tiffield Road

NN12 6HP Towcester Northamptonshire

Telefon: +44 (1327) 353437

Telefax: +44 (1327) 353564

http://www.ixthus.co.uk

Ixthus Instrumentation Limited

Telefon: +44 (1327) 353437

E-Mail: graham.pattison@ixthus.co.uk

MEPAX

Telefon: +44 (7748) 815-825

E-Mail: e.palmer@mepax.com

![]()