*1: MALDI or matrix-assisted laser desorption/ionization is a major ionization technique used in mass spectrometry, in which a sample is pre-mixed with low-molecular-weight organic compound (called a matrix) and ionized by laser irradiation.

*2: TOF MS or time-of-flight mass spectrometry is a technique that determines the mass of atoms and molecules by measuring the time-of-flight of the ions.

A brief look at mass spectrometry

Mass spectrometry is a high-precision analytical technique for determining the type and quantity of atoms and molecules contained in a sample, and their molecular structures. The operation principle of Mass spectrometry is that the atoms and molecules in the sample are ionized by several ionization methods such as an electron beam or laser, and then the mass of each ion is measured. Analysis results are obtained as mass spectrum data that shows the mass-to-charge ratio on the horizontal axis and the ion signal intensity on the vertical axis. Another major analytical technique called ‘mass spectrometry imaging’, visualizes the spatial distribution of molecules while simultaneously obtaining a mass spectrum.

A mass spectrometer consists of an ionization section for ionizing a sample, an ion separation section for separating the ions, and an ion detection section for detecting the separated ions. Mass spectrometers are often used in conjunction with various ionization and ion separation methods depending on the sample. These methods are then used in a broad range of areas including the environment, food, chemistry, and life science fields.

DIUTHAME development background

DIUTHAME is an ionization-assisting substrate consisting of extremely fine through-holes of about 200 nanometers (1 nanometer equals one billionth of a meter) in diameter developed for MALDI-TOF MS.

In mass spectrometry imaging using MALDI, a pretreatment time of roughly 30 minutes is usually required to select and prepare a matrix, apply it to the sliced sample, and wait until it dries. These problems show the need for a different ionization technique not requiring any matrix. We developed DIUTHAME for quick and easy pretreatment that only takes approximately 3 minutes after just placing it on a sliced sample. DIUTHAME also eliminates noise generated from the matrix and delivers high-quality mass spectrometry images with high measurement reproducibility. Our first DIUTHAME product was put on the market in 2018.

Expanding the DIUTHAME lineup

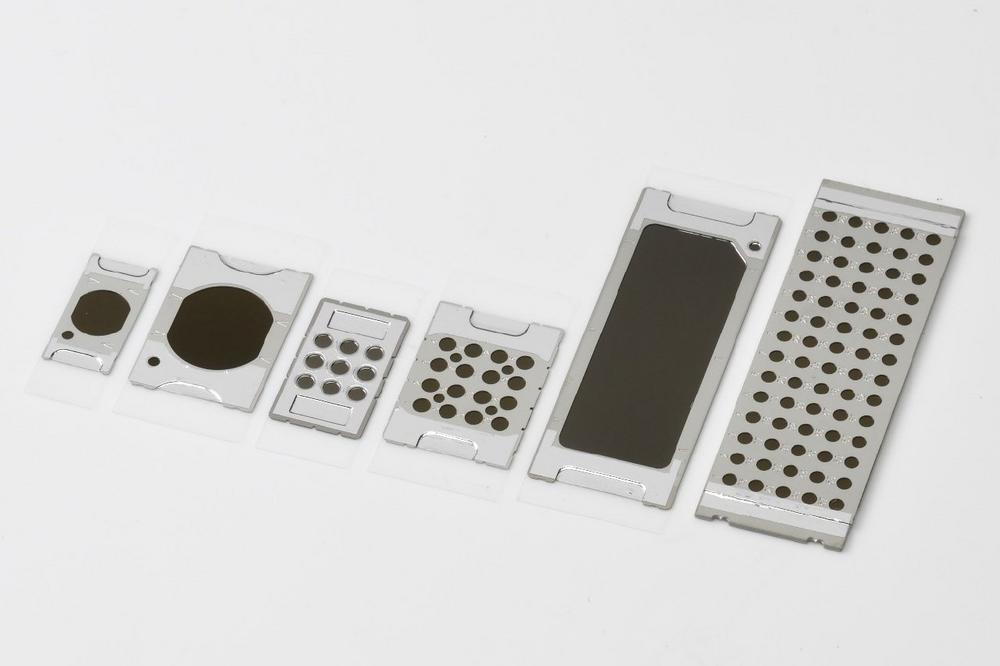

Since the release of our first DIUTHAME product, we have been developing other types of DIUTHAME substrates to respond to customer needs. For example, we provide types with a larger effective area optimized for mass spectrometry imaging dealing with large samples and also types compatible with the blotting technique(*3) often used with mass spectrometry imaging when it is difficult to slice samples into thin sections.

To meet current market needs, we have now added a new product to our DIUTHAME lineup that has an effective area optimized for measuring small samples by mass spectrometry imaging such as foreign matter contained in plant tissues or industrial materials. At the same time, we are also releasing a same-size product compatible with blotting. Moreover, our new lineup includes a 16-channel type that simultaneously measures more samples compared to the currently available 9-channel type, as well as a glass-slide size 70-channel type for mass spectrum measurement.

Adding these 4 new products to the DIUTHAME series expands our current lineup to a total of 9 product types that allow users to select the DIUTHAME that best matches their sample sizes in mass spectrometry imaging using MALDI-TOF MS. Our DIUTHAME lineup also allows simultaneous mass spectrum measurements of many samples to help streamline the R&D process and lower the analysis cost.

We will continue to develop more and more novel products in response to market needs.

*3: Blotting is a technique for transferring the components of a sample onto another object.

DIUTHAME features

1. NO matrix-generated noise

In MALDI mass spectrometry, the sample mixed with a matrix is ionized by laser irradiation and all the generated ions are then detected. At that point, the matrix is also ionized and those ions are also detected as signals in the low-molecular-weight region. These signals appear as noise making MALDI unsuitable for measuring low-molecular-weight samples. Using DIUTHAME, however, eliminates the noise generated from the matrix and ensures high sensitivity even when measuring low-molecular-weight samples.

2. Quick pretreatment and reliable measurement with high reproducibility

MALDI mass spectrometry imaging requires a pretreatment process that takes about 30 minutes to select and prepare an optimal matrix for the sample, apply it to the sample, and wait until it dries. It is also difficult to uniformly apply a matrix to the sample with an air brush, posing the problem of poor measurement result reproducibility. Devices for uniformly applying a matrix are also available but these are expensive and this task is usually carried out by hand. DIUTHAME, however, offers easy and quick pretreatment that takes approximately 3 minutes after just placing it on a sample. It also eliminates variations in measurement results that may occur depending on the worker’s skill level.

3. DIUTHAME substrate can be used with the blotting technique to expand applications of mass spectrometry imaging

In MALDI mass spectrometry imaging, the sample must be sliced into thin sections of around 10 micrometers (micrometer is one-millionth of a meter). When measuring samples with high water content such as strawberries or hard industrial materials, slicing them into thin sections can be difficult. In those cases, the sample surface components are transferred to the DIUTHAME substrate by blotting, as seen below, and set in the mass spectrometer. As a result, DIUTHAME allows mass spectrometry imaging without having to slice the sample into thin sections. This will vastly expand the range of mass spectrometry imaging applications to fields where samples could not be measured until now due to their large size, etc.

Hamamatsu Photonics Deutschland GmbH

Arzberger Str. 10

82211 Herrsching am Ammersee

Telefon: +49 (8152) 375-0

Telefax: +49 (8152) 375-199

http://www.hamamatsu.com

Public Relations

Telefon: +49 (8152) 375-185

Fax: +49 (8152) 375-199

E-Mail: rfritsch@hamamatsu.de

![]()