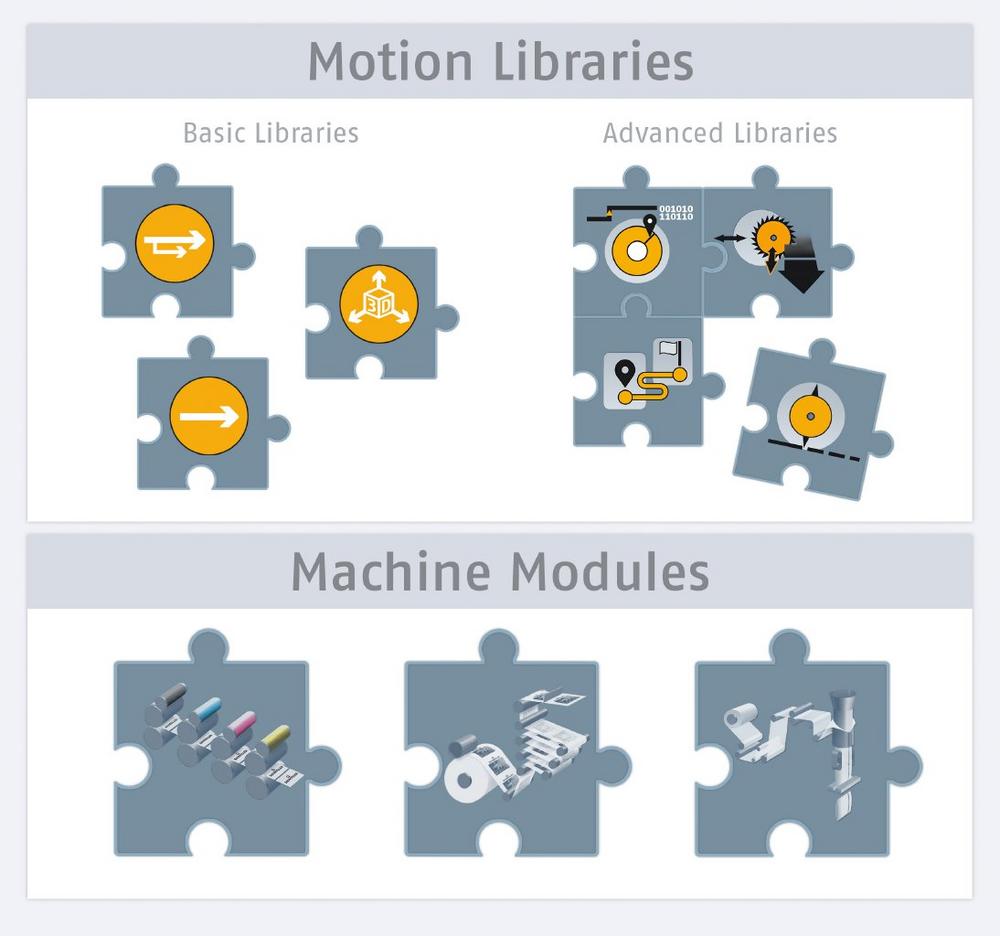

Extension of Basic Libraries

The basic library has now been expanded to include the Coordinated Motion library for motion control of up to three motor axes of a system. The 3D-Axis library offers numerous modules that are intelligently linked to provide real added value. The programming effort and thus also the time required can be reduced by up to 80 percent. This enables functionalities such as G code, coupling of axis groups, collision monitoring, tool management or geometry compensation.

Manufacturers who would like to develop multi-axis machines with basic functions such as bending, cutting or even individual motion sequences with little effort will receive a modular automation solution that can be adapted to different applications thanks to the motion libraries from Baumüller. The main advantages of using Baumüller’s machine modules for multi-axis applications are the reduced costs, the simple handling during the project planning and commissioning and therefore the much shorter time-to-market.

Skilfully combined

The motion libraries are consistent, optimally tailored to your automation tasks and build on each other. Individual industry expertise can be stored in your own libraries, managed and recalled again at any time.

Using international standards such as programming languages as per IEC 61131 and technology-specific extensions from Baumüller guarantees maximum investment security.

The motion functionalities support various control architectures and can be implemented directly in the controller on the drive-integrated controller b maXX drivePLC up to the box PC PCC-04.

Modular linking of individual modules

The advanced libraries from Baumüller are extensions of basic libraries and reproduce individual machine functions. All advanced libraries can be combined with each other.

Continuously or intermittently working machines can quickly and easily realize various tasks such as unwinding and rewinding, positioning, forming and punching with the help of the extended libraries. In this way, a high process quality is achieved with time-optimized and smooth movements.

Machine Modules

At the control level, Baumüller offers user-friendly and innovative machine modules to create optimal processes in a time-saving manner. The machine modules are available for different applications. The innovative and optimized solutions save a lot of time when parameterizing the machine. Complex motion controls can be configured in just a few steps. In the process, the customer can benefit from extensive application expertise, which is integrated into the individual machine modules.

Reusing Universal Machine Functions

Every application is unique, but that doesn’t mean having to reinvent everything – quite the contrary: In the sense of modular engineering, it is important to fall back on what is tried and true and focus on the specific task and the benefits.

www.baumueller.com/…

https://www.youtube.com/…

https://www.xing.com/…

https://www.linkedin.com/…

Based in Nuremberg, Baumüller is a leading manufacturer of electric drive and automation systems. Around 1,950 employees work on intelligent system solutions for mechanical engineering and e-mobility at six production locations in Germany, the Czech Republic, Slovenia and China as well as in over 40 branches around the world.

The range of services of the Baumüller Group includes engineering, assembly and industrial relocation as well as services, thereby covering the entire life cycle management.

Baumüller Gruppe

Ostendstraße 80-90

90482 Nürnberg

Telefon: +49 (911) 5432-0

Telefax: +49 (911) 5432-130

http://www.baumueller.com

Marketing Communications Manager

Telefon: +49 (911) 5432-319

Fax: +49 (911) 5432-231

E-Mail: stefanie.lauterbach@baumueller.com

Messe / Online-Marketing

Telefon: +49 (911) 5432-548

Fax: +49 (911) 5432-231

E-Mail: anja.andraschko@baumueller.com

Media

Telefon: +49 (170) 5516-160

E-Mail: markus.morgenweck@baumueller.com

![]()