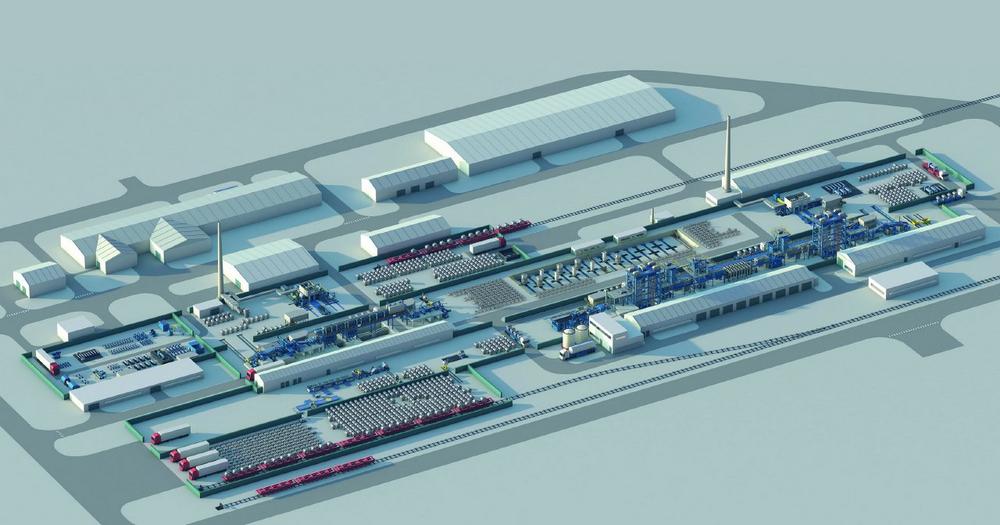

The production planning system X-Pact® MES 4.0 offers an enormous range of adaptable functions along the complete process chain with regard to plant productivity. Thanks to an advanced software architecture and its modular, extendable structure, the system will provide real economic advantages to a modern and highly productive company like MMPZ-group in times of increasing digitalization.

As an integrated solution, the X-Pact® MES 4.0 system comprises planning, support and optimization, supply and dispatch, quality control and reporting functions. The scope of supply further includes an X-Pact® Warehouse Management system for the complete production complex. Integration of the MES system will make automation consistent from basis automation (Level 1) to process automation (Level 2) and further to the production planning system (Level 3). Coil and sheet storage locations as well as cranes and transport vehicles will be integrated in the system, too.

In addition to the basic system that serves for collecting and saving production data, the MES system for MMPZ-group will include, among others, the following modules: Technical Order Generation to generate from customer orders the corresponding orders for manufacture, Production Sequencing System to determine the optimum sequence for the strips to be produced, Business Intelligence Reporting System to allow for interactive, web-based reporting for gaining information from production data, the Quality App serves for tracking coils and their status/quality, and the Warehouse Management App is used by crane drivers and quality inspectors.

The X-Pact® Automation system ordered from SMS group at an earlier date was supplied to the customer after it had passed an integration test. Commissioning on site will be accomplished together with the later ordered MES system and will include connection to the automation systems (for example X-Pact® Level 2 for the strip processing lines and X-Pact® Level 1 for the rolling mills, coil and sheet packaging lines), to the ERP system and the customer’s laboratory. Commissioning of the new works complex is scheduled to be completed in 2019.

SMS group is a group of companies internationally active in plant construction and mechanical engineering for the steel and nonferrous metals industry. It has some 14,000 employees who generate worldwide sales of more than EUR 3 billion. The sole owner of the holding company SMS GmbH is the Familie Weiss Foundation.

SMS group GmbH

Am SMS Campus 1

41069 Mönchengladbach

Telefon: +49 2161 350-4449

http://www.sms-group.com

Fachpresse

Telefon: +49 (211) 881-4449

Fax: +49 (211) 881-774449

E-Mail: thilo.sagermann@sms-group.com

Corporate Communications

Telefon: +49 (211) 881-4758

Fax: +49 (211) 881-774758

E-Mail: Birgit.Dyla1@sms-group.com

![]()