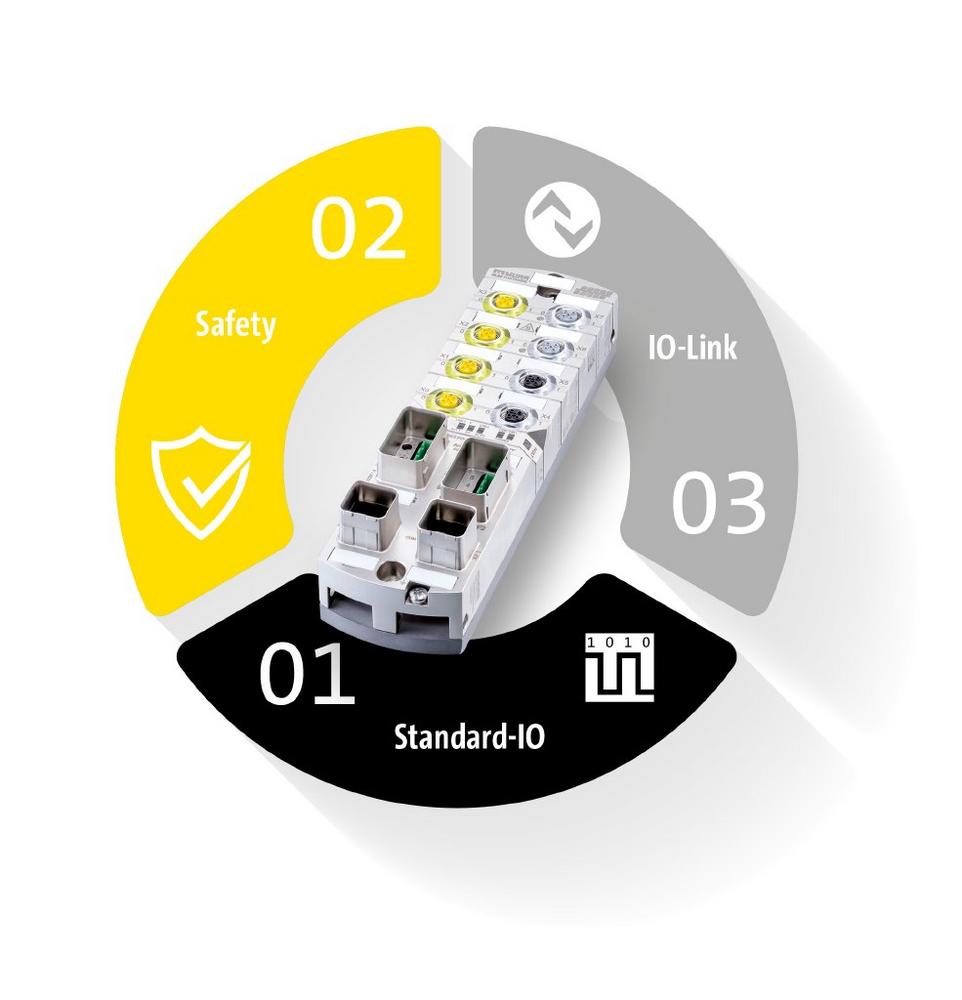

- Standard digital sensors and actuators

- Safety digital sensors and actuators

- IO-Link

This combination is new and innovative. It enables unique and groundbreaking automation concepts to be realized. Installation becomes simpler and faster.

MVK Fusion makes complex configurations easier because they can be done entirely by the engineering tool in the safety control system. Software developers and electrical engineers no longer need in-depth knowledge of other manufacturers’ tools and manuals.

MVK Fusion makes it possible to have fewer fieldbus modules per unit. Some applications might only require a single module. This opens up new opportunities for many automation applications!

One Module with Extreme Range

What makes the MVK Fusion fieldbus module unique is its variety. It combines three basic functions: standard digital sensors and actuators, safety digital sensors and actuators and IO-Link.

- The two standard digital ports can be configured as inputs or outputs – they are customizable for each application.

- The four safety ports ensure that almost all digital safety requirements are integrated into the installation.

- The two IO-Link ports offer a wide range of functions: they integrate smart devices into the fieldbus system and they also enable the system to be expanded cost-effectively via IO-Link hubs.

MVK Fusion simplifies installation by minimizing the number of modules required.

Flexibility within Safety Applications

MVK Fusion integrates all safety aspects into one module:

- Safety sensors signals are transmitted over the three safe input ports, each of which have two channels. Emergency stop buttons, light curtains, two-handed units, safety doors, etc. can be qualified up to Performance Level e.

- The safety output port has two safe outputs that can be configured according to the application (PP, PM or PPM switching). You can integrate a wide variety of actuator types like double valves and valve islands that still qualify up to Performance Level e.

- A special Class B IO-Link port ensures that IO-Link devices like valve islands and hubs can be easily and safely switched-off complying with safety standards up to Performance Level d.

MVK Fusion lets you achieve high safety standards, protecting both man and machine.

Safety Configuration within a Mouse Click

MVK Fusion makes configuring safety sensors and actuators extremely easy: select the safety function in the safety control system engineering tool, and within a few mouse clicks configuration is done.

The users – usually the software developer or the electrical engineer – do not require any special knowledge to configure the module. The MVK Fusion module eliminates the extra verification work step (CRC calculation) and doesn’t require additional manufacturer-specific software. This speeds up the process because it prevents entry of incorrect data.

High Performance

MVK Fusion is excellent for high power applications when reliability cannot be compromised. The module is one hundred percent compatible with PROFINET solutions. MVK Fusion is suitable for Conformance Class C (IRT), Shared Device and Netload Class III applications.

A Wide Range of Uses and Comprehensive Diagnostics

- Rugged, fully-molded metal housing made for a wide range of uses – like extreme welding applications.

- MVK Fusion saves error information with a time stamp on an integrated web server, even in the event of power failure, helping you identify errors and reduce downtimes.

- The safety address is set directly on the module via rotary switch – MVK Fusion can also be restored to its default setting via the address 000.

- The module functions at high outdoor temperatures (up to 60° C) in combination with high currents (up to 16 A). We offer an optional heat sink is for these extreme conditions, which extends the life of the module.

- Unique to the market, the module can be used in at very high altitudes: up to 3,000 meters (10,000 feet).

- Every single channel is monitored for problems like overloads, sensor shorts or short circuits – the comprehensive diagnostics detect errors quickly, so they can be analyzed and fixed.

Murrelektronik GmbH

Grabenstraße 29

71570 Oppenweiler

Telefon: +49 (7191) 47-0

Telefax: +49 (7191) 47-491000

http://www.murrelektronik.com

Corporate Marketing

Telefon: +49 (7191) 47-4318

Fax: +49 (151) 438544-70

E-Mail: Mackenzie.Regorsek@murrelektronik.de

![]()