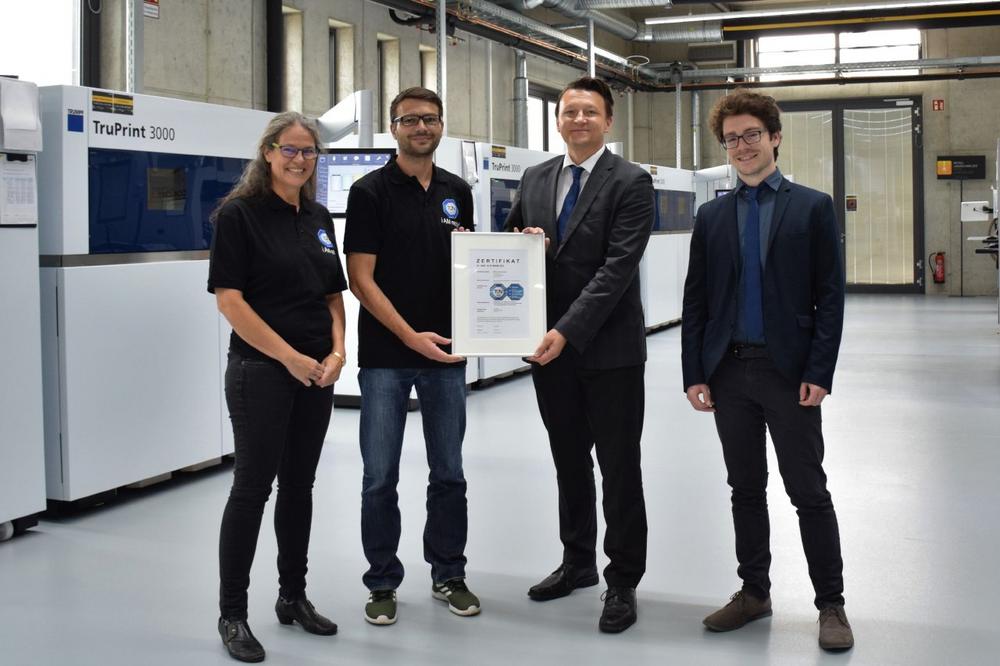

TÜV SÜD certification

TÜV SÜD started the “Additive Manufacturer” certification program as an independent evaluation procedure designed to ensure the service and product quality of 3D-printed precision component manufacturers. It tests company leadership, customer and order management, and production – from material handling to manufacture and finishing to quality assurance. The certificate verifies conformity to reproducible and transparent additive manufacturing (AM) processes and an AM-appropriate working environment. Best-practice methods in the immediate production environment also lead to continuous improvement in manufacture, machine handling, and occupational safety.

Continuous improvement via certification

“Because they involve professional feedback, certificates prompt continuous improvement measures,” says Christoph Hauck, managing director at toolcraft and the person primarily responsible for AM. For the customer, certificates facilitate the purchasing process, since it is not only product quality, but also reliable transaction processing, that are verified. “They also reduce the effort invested in individual tests,” says Hauck. toolcraft works continuously on the improvement of the 3D printing process and of the entire process chain. The new metal laser melting centre also includes a laboratory for analysing material and manufactured samples. The dynamic strengths of various metals are assessed via dynamic fatigue testing. Further investments are planned in the area of build-up welding (DED/LMD) of metals.

toolcraft is a pioneer of forward-looking technologies, such as 3D metal printing and the construction of customised turnkey robotics solutions. The company tests and develops innovative engineering processes until they are ready to be used on production lines. As a provider of comprehensive solutions, toolcraft covers the entire process chain, from the initial idea to manufacturing, quality assurance and testing in the areas of CNC machining, 3D metal printing, injection moulding, spark erosion (EDM) and mould making. Its clients include market leaders in the semiconductors, aerospace, medical technology, optical, special machinery manufacturing, motor sports and automotive industries. Building close working relationships with collaborative partners as well as universities, other institutions of higher education and research centres is an important part of its corporate philosophy. The medium-sized family-owned company, located in Georgensgmünd and Spalt, was founded by Bernd Krebs in 1989.

toolcraft AG

Handelsstraße 1

91166 Georgensgmünd

Telefon: +49 (9172) 6956-0

Telefax: +49 (9172) 6956-560

http://www.toolcraft.de

Telefon: +49 (9172) 6956-172

E-Mail: tinahartmann@toolcraft.de

![]()