The control cable is approved for widespread use in North America by virtue of its multiple NEC and NFPA certifications. Thanks to the tried-and-tested UL and c(UL) listings for the USA and Canada (such as MTW, TC-ER, WTTC and CIC), there is less need to grapple with the often complex, time-consuming overseas approval procedures. Now, users only need to keep one multi-standard cable type in stock – a clear advantage that benefits exporters in particular.

The cable comes in the Core Line performance class and is ideally suited to continuous use in power chains with moderate to high travel paths and acceleration, in non-stationary machine parts, in linear robots and handling systems, and in wind turbines (Wind Turbine Tray Cable). The two UL listings of MTW (Machine Tool Wire) and TC-ER (Tray Cable-Exposed Run) in particular allow for flexible, standards-compliant use of the cable in industrial machines, as well as fixed installation in open cable trays with one and the same cable. The ÖLFLEX® CHAIN TM and ÖLFLEX® CHAIN TM CY are designed for North American operating voltages of 600 volts or 1,000 volts (WTTC).

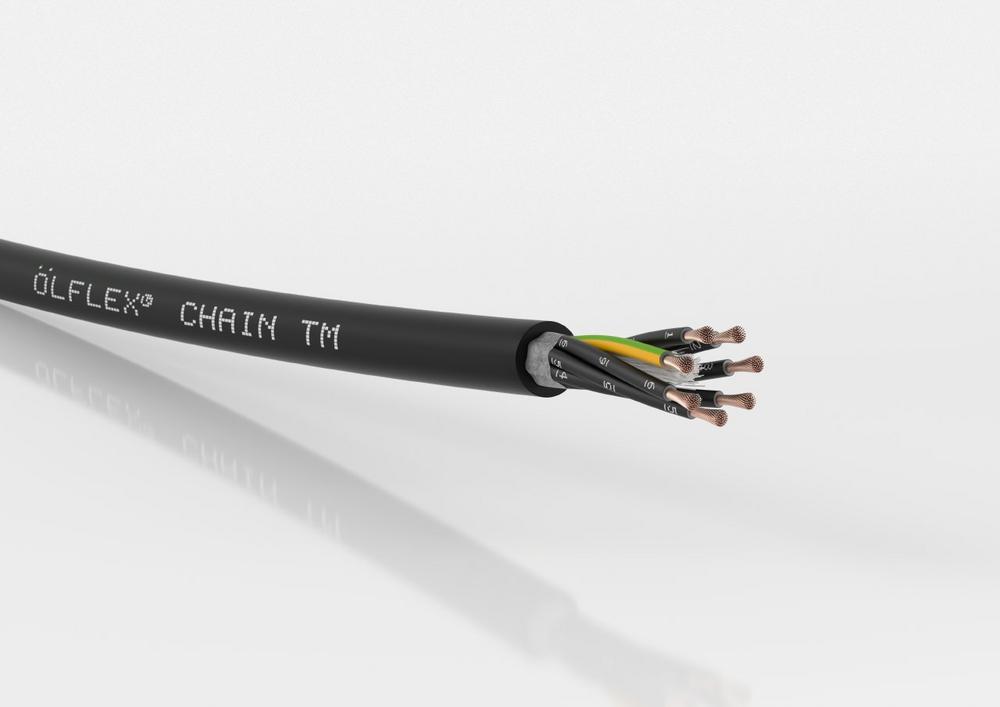

Thanks to the strand made from extra-fine copper wire from conductor class 6 and the special stranding technique, the cable can be used in constantly moving applications in drag chains involving up to 5 million bending cycles, as well as moderate torsion applications in wind turbines involving rotational angles of +/- 150° per metre. On the shielded CY version, tin-plated copper braiding provides reliable protection against electromagnetic influences and ensures compliance with EMC regulations. The outer sheath is made from a specially designed thermoplastic polymer, which makes the cable resistant to mineral oil-based lubricants (UL Oil Res I/II) and other chemicals. The entire cable design is highly flame-retardant according to CSA FT4. As the cable is designed for a wide temperature range from -40 to +90 degrees Celsius in the case of fixed installation, it is also suitable for outdoor applications in harsh environments. Furthermore, the cable is UV-resistant and suitable for direct burial according to the US standard.

Visit Lapp at SPS IPC Drives from 28 to 30 November in Nuremberg in Hall 2, Stand 310.

Based in Stuttgart, Germany, the Lapp Group is the global market leader in integrated solutions and branded products in the field of cable and connection technology. The Group’s portfolio includes standard and highly flexible cables, industrial connectors and screw technology, customised system solutions, automation technology and robotics solutions for Industry 4.0 and the Smart Factory. The Lapp Group’s core market is in the industrial machinery and plant engineering sector. Other important sales markets include the food, energy, mobility and life sciences industries.

The Lapp Group has remained in continuous family ownership since it was founded in 1959. In the 2015/16 business year, it generated consolidated revenue of 901 million euros. Lapp currently employs approximately 3,440 people across the world and has 17 production sites and over 40 sales companies; the company also works in cooperation with around 100 foreign representatives.

U.I. Lapp GmbH

Schulze-Delitzsch-Str. 25

70565 Stuttgart

Telefon: +49 (711) 7838-01

Telefax: +49 (711) 78382640

http://www.lapp.com

Public Relations & Media

Telefon: +49 (711) 7838-5170

Fax: +49 (711) 7838-5550

E-Mail: Markus.j.mueller@lappkabel.de

Telefon: +49 (711) 7838-01

Fax: +49 (711) 7838-2640

E-Mail: irmgard.nille@in-press.de

![]()