“What impressed us at KHS wasn’t just the aseptic system itself but also the extremely positive contact we had with all those involved in the project. Everybody was extremely targeted and solution-oriented in this joint undertaking,” smiles Josef Simon, head of Production and Technology at the Niederösterreichische Molkerei or Lower Austrian Dairy (NÖM). With a total of 721 employees the group achieved a turnover of about €353 million in 2016, with the largest share attributable to NÖM AG. NÖM makes its biggest sales on the local market and in Germany and Italy. PET bottling plays a decisive part in its operations. Here, particular attention is paid to the hygiene and reliability of its plant technology. “In this respect we’ve had very good experience with KHS for years,” says Simon.

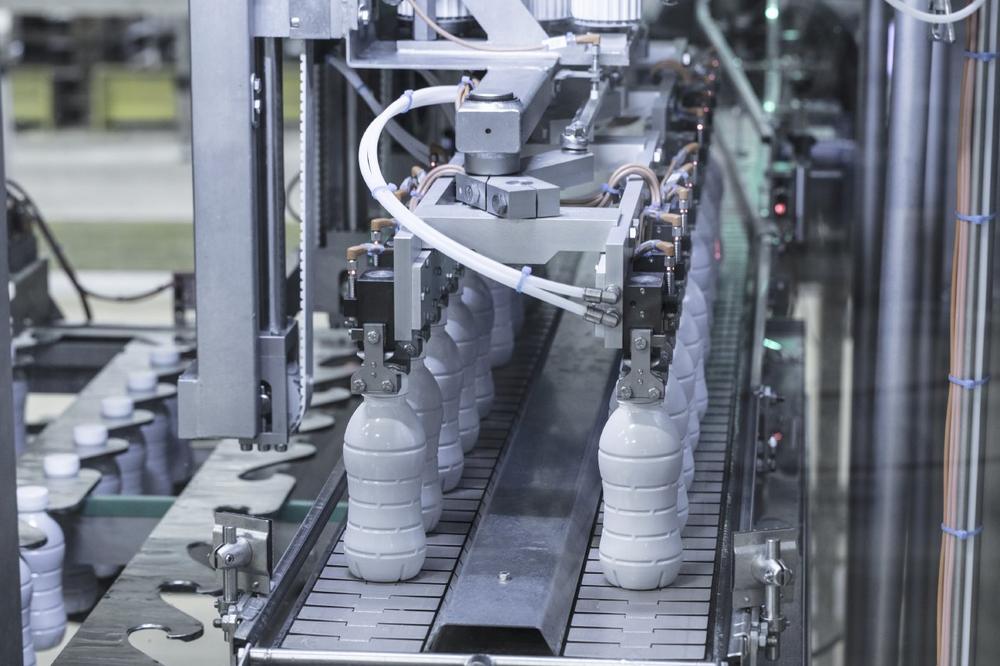

Once the new system had been installed, NÖM ran an extensive sterile test. A quarter of a batch of 40,000 sample bottles was assessed; there were no grounds for complaint whatsoever. KHS achieved such a good performance by focusing on the aseptics during the planning of its filler, resulting in a very small aseptic zone on this compact modular linear machine.

Great flexibility for a large product portfolio

As in its normal course of work the dairy often needs to react to the demands of the retail trade at short notice, requiring it to change products and formats over, the flexibility of the system is important. “Customers can switch between different bottle formats in the space of about ten minutes,” states Thomas Redeker, sales director for Dairy Europe at KHS. This allows NÖM AG to easily manage its extensive product portfolio. The new line fills liquid milk to viscose mixed milk beverages in formats from 250 milliliters to 1.5 liters. For example, the KHS Innosept Asbofill ABF 711 has an output of up to 15,000 half-liter bottles an hour and a maximum capacity of 9,000 bottles per hour for the 1.5-liter container.

On the dairy market KHS customers profit from the years of experience clocked up by the Dortmund group. These include its customer-oriented service concept. As recently as in 2015 KHS presented a light 1.0-liter PET bottle for milk and mixed milk beverages weighing only 20 grams, winning it the World Beverage Innovation Award. In addition to the Innosept Asbofill ABF 711 the systems supplier also markets a 611 variant of the aseptic machine. Both models have been designed for the small, medium and large filling volume range and especially to satisfy the specifications of milk, mixed milk beverages and protein, yogurt and coffee drinks in PET and HDPE bottles. A fruit chunk dosing unit is therefore also available for chunks of up to 10 x 10 x 10 mm in size.

KHS is one of the leading manufacturers of filling and packaging systems for the beverage, food and non-food industries. The KHS Group includes the following companies: KHS GmbH, KHS Corpoplast GmbH, NMP Systems GmbH and numerous subsidiaries outside Germany.

KHS GmbH manufactures modern filling and packaging systems for the high-capacity range at its headquarters in Dortmund, Germany, and at its factories in Bad Kreuznach, Kleve and Worms. The KHS Group’s PET expertise is pooled at KHS Corpoplast GmbH in Hamburg, Germany, where innovative PET packaging and coating systems are developed and produced. NMP Systems GmbH, a wholly-owned subsidiary of KHS GmbH based in Düsseldorf in Germany, designs and markets new, resource-saving packaging systems for PET bottles.

In 2016 KHS and its 4,995 employees achieved a turnover of around €1.18 billion within the Salzgitter consolidation. The companies in the KHS Group are 100% subsidiaries of the MDAX-listed Salzgitter AG corporation.

KHS GmbH

Juchostr. 20

44143 Dortmund

Telefon: +49 (231) 569-0

Telefax: +49 (231) 569-1541

http://www.khs.com

Presse- und Öffentlichkeitsarbeit

Telefon: +49 (251) 62556121

Fax: +49 (251) 62556119

E-Mail: wopen@sputnik-agentur.de

![]()